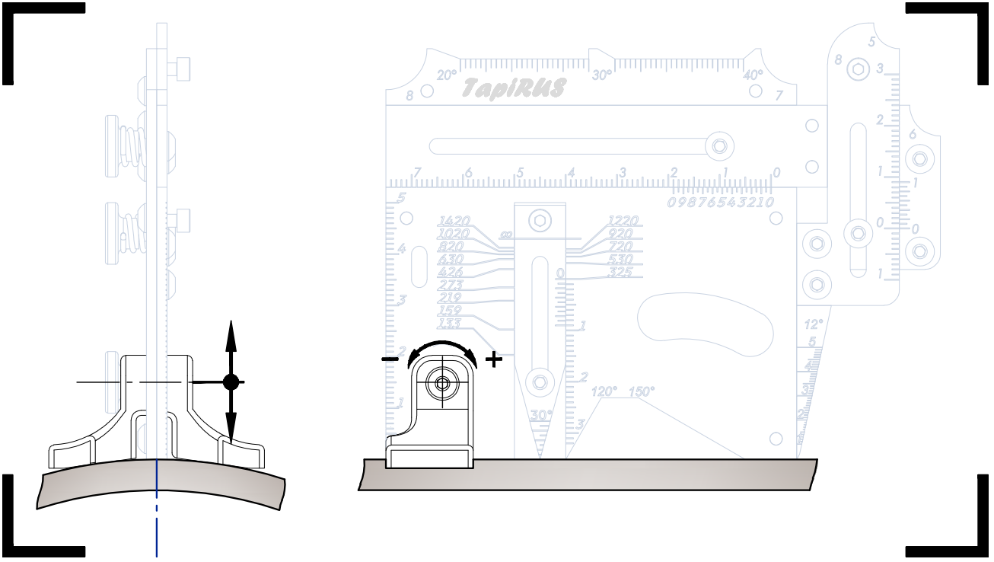

Measurement of penetration depth between the sealing run

Penetrations between sealing run - longitudinal hollows between two adjacent sealing runs. It is defined as the height difference in the place of the highest elevation of the weld metal above the surface of the welded parts and in the place of depression

positioning the welding gauge

- Position the welding gauge perpendicular to the weld, close to the fusion line.

- For greater stability of the welding gauge when taking measurements, use the pivots

˟ the parameter measured during monitoring process is highlighted in red

measurement taking

- Adjust the linear member 3 so that the taper gauge 5 is above т. 1, corresponding to the height of the lower roller.

- Lower the top High-Lo arm 4 until the taper gauge 5 makes contact with the weld surface.

- From the vertical scale H, take the readings of the parameter h for т. 1.

- Without changing the position of the welding gauge, adjust the linear member 3 so that the taper gauge 5 is above т. 2. lower the top High-Lo arm 4 until the taper gauge 5 makes contact with the surface of the weld joint.

- From the vertical scale H, take the readings of the parameter h

- To obtain the desired parameter s, measure the difference between the values of the parameter h as illustrated.