TapiRUS - do more!

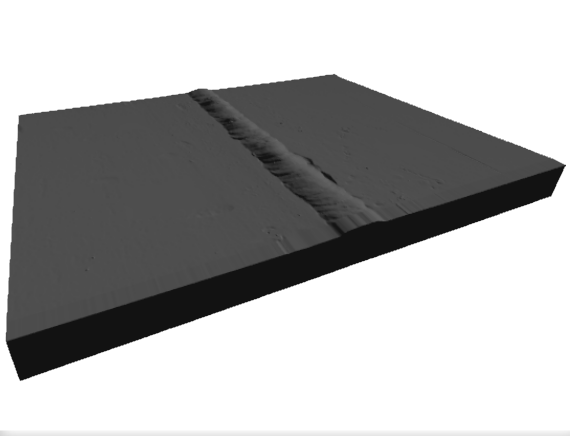

Choose weld type

STAGES

Preliminary Inspection

Is mainly carried out with the aim of identifying deformations, surface cracks, chipping marks, grinding

marks, cavities and other discontinuities;It is also meant for: checking the geometric dimensions of

work-pieces, semi-finished products and parts, validation of identified deformations and surface

discontinuities.

Inspection of finished welds

Is carried out in order to identify deformations, surface cracks, undercuts,

craters, worm holes , pores, cavities, deviations of the shape of the joints; checking the

geometric dimensions of the welds and the admissibility of the identified deformations,

surface discontinuities , defects in the shape of the welds and other discontinuities.

Inspection during assembly

Is carried out with an aim of identifying and verifying the provision of acceptable gaps, the shape and

size of the edges and the geometric position of the axes and surfaces of the assembled elements;

Inspection during Eploitation

Is carried out in order to identify changes in the shape of technical devices and structures, surface defects in the material and welded joints (surfacing) formed during operation (cracks, corrosion damage, deformation, etc.)

Also, inspection methods using TapiRUS can be developed for the following types of connections (structures):

● T-JOINT welded pipes

● lap weld

● pipe + sheet

● welded joint of spiral tubes

Contact us

Please contact us for any enquiries