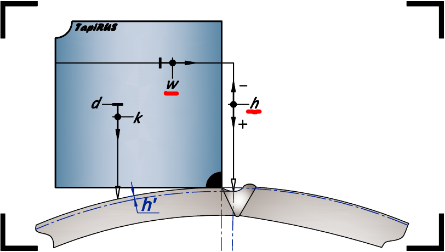

Height measurement of the incomplete filling and the crater depth

Incomplete filling - It’s a continuous or an intermittent longitudinal groove on the surface of the weld formed due to insufficient filler material

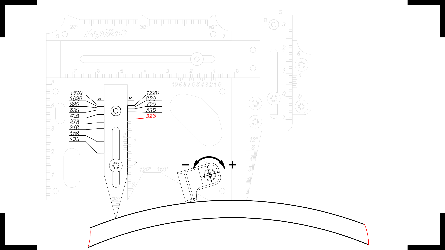

positioning the welding gauge

- Set the welding gauge at the zero position

- Pull the fillet arm 2 out of the main gauge plate 1, matching the mark with a value corresponding to the diameter of the pipe being monitored

- Fix and lock the stop position by tightening the fillet arm rivet 6.

- Position the welding gauge on the test object.

- After rearranging the pivots in the groove located on the right side of the welding gauge, adjust them until they come into contact with the inspected object.

- Lock the pivots in this position as shown by the illustration

˟ красным цветом выделены параметры, подлежащие измерению

measurement taking

- Adjust the linear member 3 so that the taper gauge 5 is above the point of measurement (at the point of greatest concavity).

- Take the value of the parameter w on the horizontal scale W, and subsequently the readings of h from the vertical scale H

- Lower the top High-Lo arm 4 so that the taper gauge 5 makes contact with the surface of the test object at the point of measurement.