Depth measurement of surface discontinuities on the base metal: scartches, grinding marks, surface torn

Scratch (grinding marks) - Damage to the surface of the pipe as a result of its dynamic interaction with a moving solid body with sharp edges.

Surface torn - Surface torn differs from a scratch by a slightly larger width and jagged edges.

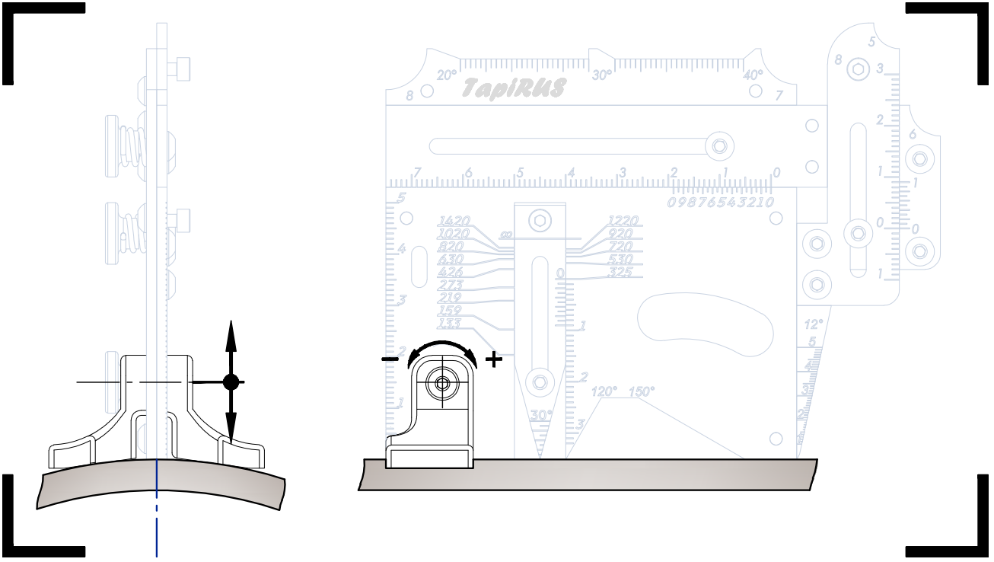

positioning the welding gauge

- Position the welding gauge on the surface of the base metal at a minimum distance from the measurement point.

- For greater stability of the welding gauge during measurement takings, use the pivots

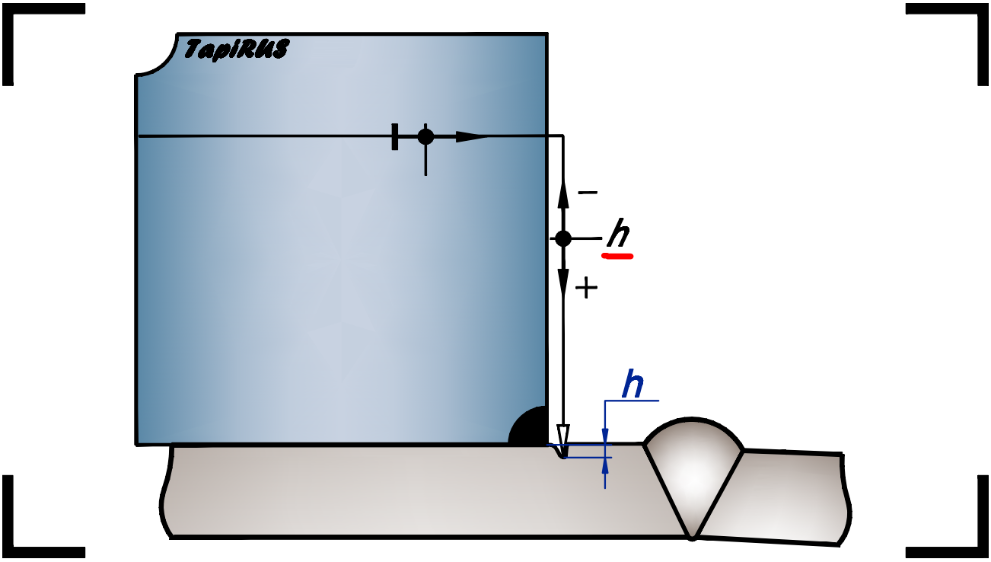

˟the parameter measured during monitoring is

highlighted in red

measurement taking

- Adjust the linear member 3 so that the taper gauge 5 is above the measurement point.

- Lower the top High-Lo arm 4 until the taper gauge 5 makes contact with the surface of the test object at the point of measurement.

- Take the value of the parameter h from the vertical scale H as illustrated